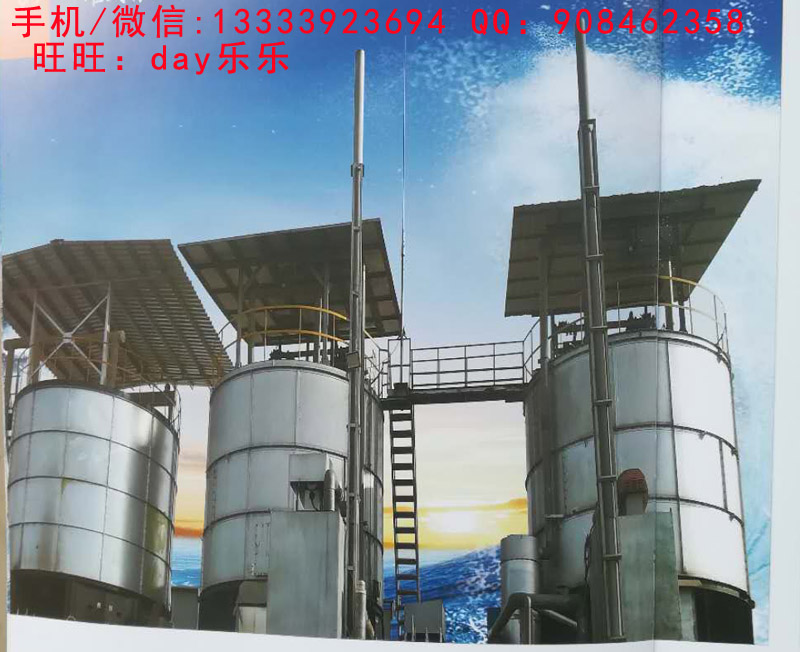

不锈钢有机肥发酵罐养殖场粪便牛羊鸡猪粪好氧发酵全套设备生产线

细节展示彰显做工

驱动

采用液压驱动,推力大,可以保证罐体内腐

设计

熟物满载负荷运行,确保运行稳定,维修成

本低

有机肥发酵罐

养殖废弃物处理整体解决方案

PROFESSIONAL SOLUTIONS FOR LIVESTOCK WASTE TREATMENT

有机肥发酵罐工艺流程储料仓1储料仓2上部送风物料破碎混合玉B好生物除臭装置远程自动控制:液压动力站·下部送风

适用范围广泛

WI D E A PP L I C AT I O N RA N G E

秸秆

糟渣糠粕

锯沫

禽畜粪便

淤泥污泥

垃圾

防腐有机肥快速发酵设备均采用PLC程序控制,耐用与粪便接触部分全部采用不锈钢,耐防腐,使用寿命长隔热罐体内部采用聚氨酷做保温层受外界影响小处理,上料、发酵、温控、干燥和出料全过程自动控制,确保一年四季发酵。

以下是不锈钢有机肥发酵罐养殖场粪便牛羊鸡猪粪好氧发酵全套设备生产线细节展示彰显做工的具体内容:

该设备生产线采用液压驱动方式,推力大,可保证罐体内废弃物充分腐熟。同时,其设计注重实用性,上部送风口的设计以及物料破碎混合装置等配置,有助于提高生物除臭效果。

该设备生产线采用PLC程序控制,耐用且与粪便接触部分全部采用不锈钢材质,耐防腐且使用寿命长。此外,其还具备隔热保温功能,可减少外界对发酵过程的影响。

该设备生产线可广泛应用于各种废弃物的处理,如秸秆、糟渣、糠粕、锯沫等禽畜粪便淤泥以及污泥垃圾等,可以实现对各种不同废弃物的快速发酵处理。同时,该设备还具有自动化程度高的特点,可以实现上料、发酵、温控、干燥和出料等全过程的自动控制。

综上所述,该不锈钢有机肥发酵罐养殖场粪便牛羊鸡猪粪好氧发酵全套设备生产线,通过优异的设计及先进的生产工艺展示出高质量的性能,可以帮助解决目前行业面临的一系列难题和问题,且整体技术已经处于先进水平,可在农业生产中发挥重要作用。

Stainless steel organic fertilizer fermentation tank, farm manure, cow, sheep, chicken, pig manure, aerobic fermentation complete equipment production line

Detail display showcases craftsmanship

drive

Adopting hydraulic drive with high thrust can ensure internal corrosion of the tank body

design

Mature products operate at full load to ensure stable operation and maintenance

Low cost

Organic fertilizer fermentation tank

Overall solution for livestock waste treatment

PROFESSIONAL SOLUTIONS FOR LIVESTOCK WASTE TREATMENT

Organic fertilizer fermentation tank process flow Storage silo 1 Storage silo 2 Upper air supply material crushing Mixing jade B Good biological deodorization device remote automatic control: Hydraulic power station · Lower air supply

Wide application range

WI DE A PP L I C AT I O N RA N G E

straw

Lees and bran meal

Sawdust

animal manure

Sludge

garbage

The anti-corrosion organic fertilizer rapid fermentation equipment is all controlled by PLC program, and the durable and fecal contact parts are all made of stainless steel, which is corrosion-resistant and has a long service life. The insulation layer inside the tank is made of polyurethane, which is minimally affected by external factors. The entire process of feeding, fermentation, temperature control, drying, and discharge is automatically controlled, ensuring fermentation throughout the year.

The following is a detailed display of the production line of the complete set of equipment for aerobic fermentation of cow, sheep, chicken, and pig manure in the stainless steel organic fertilizer fermentation tank farm, highlighting the specific content of the workmanship:

The production line of this equipment adopts a hydraulic drive method with high thrust, which can ensure that the waste in the tank is fully decomposed. At the same time, its design emphasizes practicality, with the design of the upper air supply outlet and the configuration of the material crushing and mixing device, which helps to improve the biological deodorization effect.

The production line of this equipment adopts PLC program control, which is durable and all parts in contact with feces are made of stainless steel material, resistant to corrosion and has a long service life. In addition, it also has thermal insulation function, which can reduce external influence on the fermentation process.

The production line of this equipment can be widely used for the treatment of various waste materials, such as straw, residue, bran, sawdust, and other livestock manure sludge, as well as sludge garbage. It can achieve rapid fermentation treatment of various types of waste. At the same time, the equipment also has a high degree of automation, which can achieve automatic control of the entire process of feeding, fermentation, temperature control, drying, and discharge.

In summary, the complete set of equipment production line for aerobic fermentation of cow, sheep, chicken, and pig manure in the stainless steel organic fertilizer fermentation tank farm has demonstrated high-quality performance through excellent design and advanced production processes, which can help solve a series of difficulties and problems currently faced by the industry. Moreover, the overall technology is at an advanced level and can play an important role in agricultural production.